Better Products by Design

ROTATION MOLDING PRODUCT DESIGN SERVICES

Rotomolding Design for Manufacturing Services from Start to Finish

Early collaboration is the key to Design for Manufacturing (DfM) at EnviCor. By engaging us early on in the process, you reap the maximum benefit of our extensive expertise in all aspects of design development and production. Let EnviCor product design services help you avoid costly mistakes and delays while shaping your concept for the highest quality, functionality, efficiency, and economy in manufacturing.

OUR DESIGN PROCESS INCLUDES

Feasibility Assessment: Wondering if your metal or fiberglass part can be produced more effectively with rotomolded plastic? We’ll tell you the pros and cons and help you make the right decision.

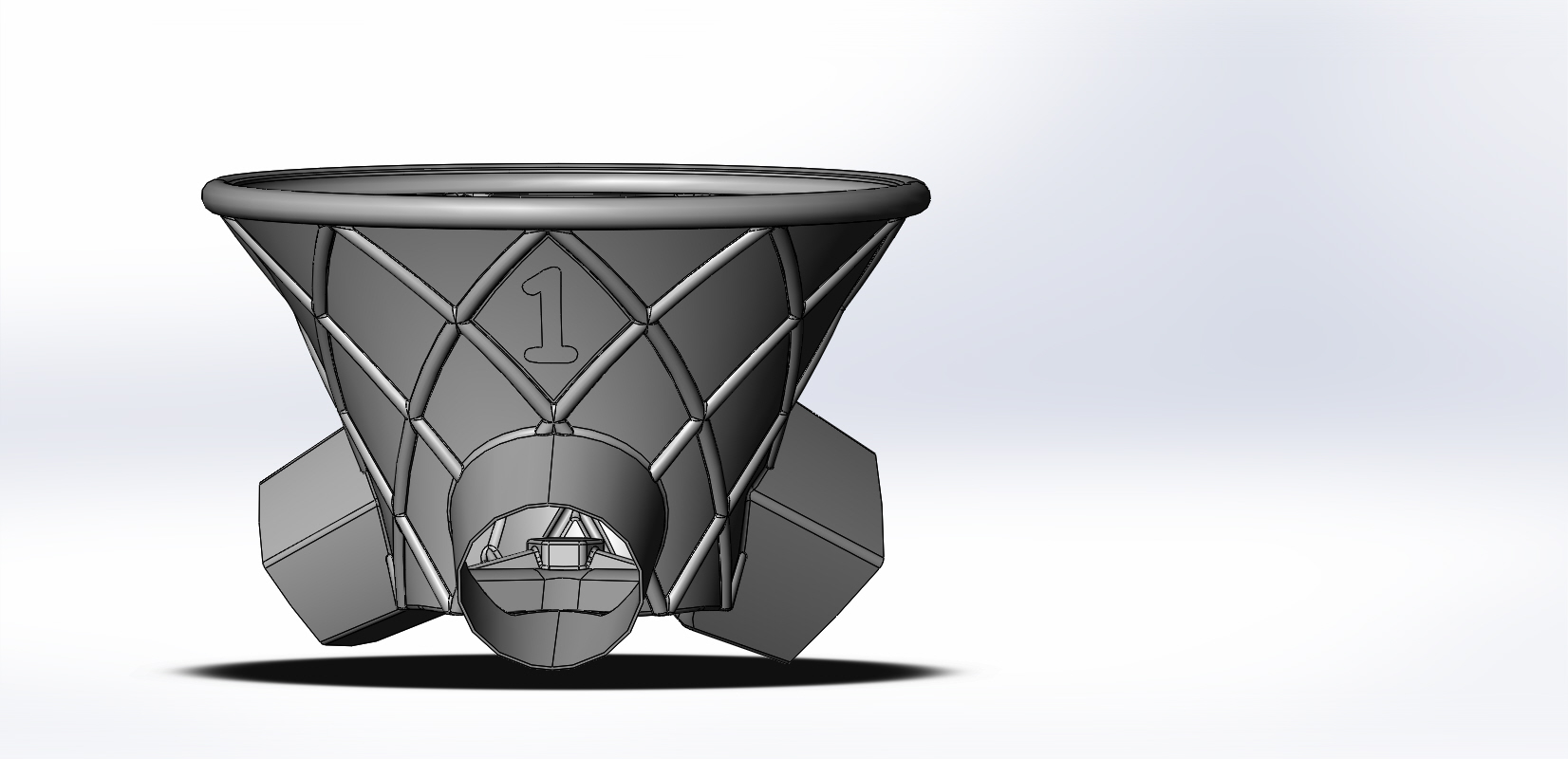

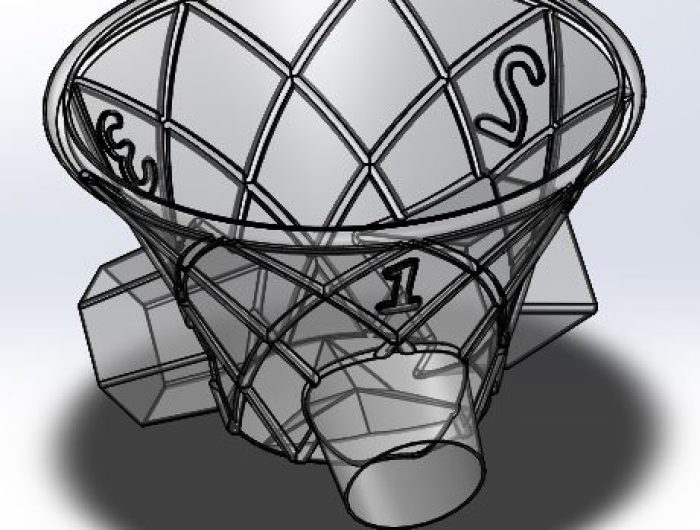

Design Conceptualization: Give us a sketch, 3D model, or physical sample, and we’ll help you refine the design into something that can be successfully rotomolded. We focus on wall thickness, draft angles, and other features that affect moldability.

Mold Design: Generate mold designs that are capable of making high-quality parts repeatedly.

Mold Build: Management and/or support of the mold-building process, from selection of mold builder to approval of the mold.

Material Recommendations: From your specs and requirements, we’ll recommend the best resin or compound for the strength, flexibility, UV stability, and chemical resistance you need.

Molding Process Optimization: When you are making hundreds or thousands of something, our team will work to ensure that we are making the process as efficient and repeatable as possible.

Quality Program: Different parts require different levels of quality control. We work with our customers to develop quality programs tailored to their business and individual part needs.

OPTIMIZED FOR QUALITY AND ECONOMY

The earlier our design team is involved, the better. EnviCor’s DFM experts make design recommendations based on manufacturability and long-term product performance. We design with an eye toward durability, repeatability, and process efficiency.

DESIGNED WITH END-USE IN MIND

From agriculture to furniture, food service, and more, EnviCor tailors the design of your part to its ultimate use and user. Every step of the way, we remain fixed on the goal of delivering the finest product to market as quickly and economically as possible.

GET ROTOMOLDING

DONE RIGHT, RIGHT HERE.

When you bring EnviCor onboard, you’re getting much more than a disembodied voice on the phone. You’re getting a team of partners with deep experience in all aspects of rotational molding. You’re getting hands-on collaboration and keen attention to every detail, every step of the way. And you’re getting rotomolding done right, with EnviCor.