At EnviCor, quality is top of mind, all the time. In fact, safeguarding quality is inherent in everything we do. From raw material selection to the final seal of approval, EnviCor’s overarching goal is to deliver exceptional rotomolded components that perform reliably, safely, and to the exacting standards our customers demand.

QUALITY ASSURANCE

Tailored Quality Programs

Every part, every customer, and every application is unique. Therefore, each needs to be evaluated for quality in its own particular way. Some parts need only a visual inspection to determine their quality. Others may require a suite of laboratory tests. EnviCor has all the relevant tools and methods at our disposal. Our quality assurance team works with each customer to build a testing program that aligns with the functional and regulatory requirements of their part. Specifications are then written to address customer priorities such as durability, shape, dimension, safety, environmental exposure, and of course, regulatory compliance.

Safety, Compliance

& Certifications

Whether producing a complex plastic component or a simple UCO storage tank, EnviCor always emphasizes quality and safety standards, ensuring compliance with all relevant health and safety regulations. EnviCor’s rotomolded products are engineered for durability and performance in demanding applications such as wastewater treatment and fuel storage. Customers can trust EnviCor to provide custom solutions that are built to last and safe to use, reducing risks without compromising performance over a long working life.

A Culture of Quality

Our customers may have very high expectations, but they are never higher than our own. At EnviCor, every employee is empowered to “Be the Customer.” This critical mindset lets us see each product from the perspective of those who we’re making it for. Equipped with considerable technical training, EnviCor team members feel emboldened to question, verify, and continuously improve everything they touch. This culture elevates quality assurance in every step of every process, ensuring that every EnviCor product is of the very highest caliber.

Testing, Gauging, Inspection & Measurement

Living up to our promise of providing only parts of the highest quality requires adhering to industry best practices and employing advanced testing methods. These by include:

- Material verification: melt flow / melt index testing; material certification; checks for uniformity.

- Dimensional controls: precision measurement tools, jigs, gauges, digital calipers to ensure parts match critical dimensions.

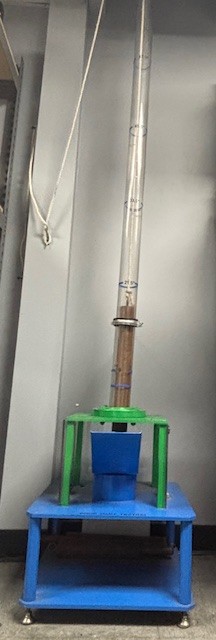

- Non-destructive testing: hydrostatic testing for tanks, ultrasonic evaluation especially for sintered polyethylene tanks to detect internal flaws or incomplete fusion.

- Impact, stress, and environmental performance: tests under load, under temperature extremes, under chemical exposure, as required.

- Statistical process control (SPC) and process monitoring: tracking heating/cooling curves, mold rotation, temperature, airflow, etc., to catch trends before they become defects.

Design & Tooling for Quality

It is often said that quality begins with design. To EnviCor, that means building parts that are not only functional, but designed to be imminently manufacturable, consistent, and durable. Rotational molding demands a specific skillset, and high-quality results are dependent on a few key aspects of the process. EnviCor products are designed from the start with a focus on these critical areas:

- Mold and part design must incorporate precise wall thickness, corner radii, and draft angles to enable even material flow and smooth release.

- Tooling and molds must be built and maintained to tight tolerances in order to achieve consistency of parts from run to run.

- Maintenance of molds and equipment must be regularly validated and meticulously maintained to prevent drift, warpage, and other defects.

Look to EnviCor for Quality Rotomolding

EnviCor is widely known for building quality parts through rotational molding. Our customers are confident that, with us, they are guaranteed to receive:

- Durable parts that are built to last, cutting risk, minimizing maintenance, and defraying replacement costs.

- Certainty that parts are safe to use and compliant with required regulations.

- Rotational molding expertise with custom quality assurance protocols designed to your specifications.

- Consistency in dimensional accuracy, appearance, and performance on every run.

Let us show you what EnviCor Quality Assurance can do for your firm. Get in touch today or request a quote.